SoudaFrame SWI was specially developed for the pre-wall installation of windows and doors in the insulating layer. The pre-wall window installation system consists of lightweight L-shaped frame elements made of glass fibre reinforced plastic (GFRP), metal corner connectors, extension pieces and support elements (SWI Corner, SWI Link and SWI Support), a specially developed high tack adhesive (Soudaseal SWI) for an air- and waterproof installation and sealing of the frame to the wall, as well as SWI Clips that allow for an easy one-person installation and sealing with uniform joint dimensions.

Advantages:

- Extra-long profile lengths (= less connections)

- High load-bearing capacity

- Very high thermal efficiency

- 100 % form stable (does not shrink or expand)

- One-man installation (for normal size windows)

- Very fast frame assembly due to precisely fitting plug-in connectors: SWI Corner and SWI Link

- Standardised joint dimension around the window frame thanks to the SWI Clip

- Easy to install both level and square, only 1 adjustment needed for the entire frame (instead of having to fix and adjust each item separately)

- Suitable for the installation of windows with fall protection

- BIM ready → http://bim.soudal.com

- Guaranteed compatibility with all SWS products

- Passive House Certified Component for 3 different climate zones

- Suitable for burglar-resistant installations according to classes RC2 and RC3

Components:

SoudaFrame SWI

The SoudaFrame SWI profiles form the base of our pre-wall window installation system. Made of high-quality GFRP, this innovative lightweight material offers a high load-bearing capacity combined with high rigidity. Easy, safe and error-free to connect, the frame elements are a guarantee for fast assembly and high flexibility on the construction site. The elements are available in 4 dimensions (90, 130, 160 and 200 mm) with a length of 2,2 meters.

SoudaFrame SWI Corner

Zinc plated metal connection piece for an easy, safe and error-free connection of the frame elements. The innovative plug-in solution enables a fast installation and high flexibility on the construction site.

SoudaFrame SWI Link

Zinc plated metal connector to connect two frame elements at e.g. large windows, re-use of cut-off frame elements to reduce waste.

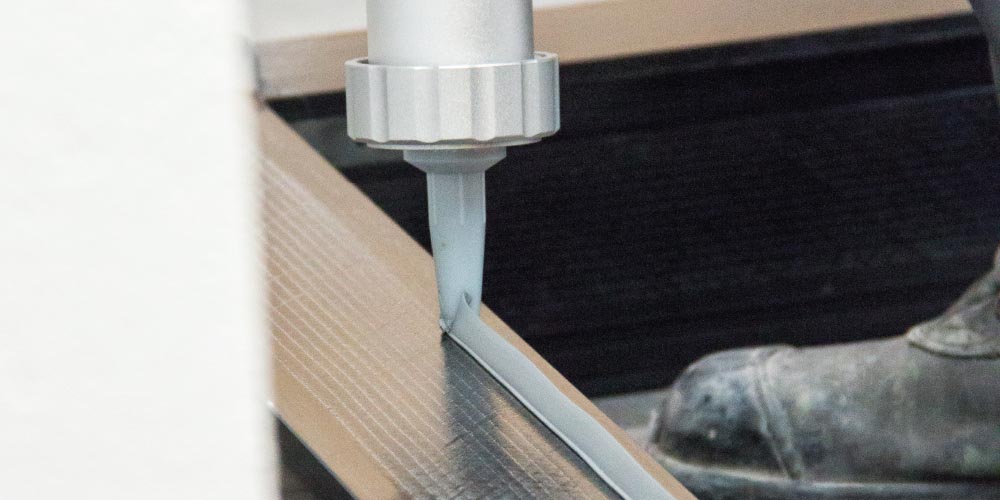

SoudaFrame SWI Clip

Practical installation tool for an temporarily fixation of the window frame in the pre-frame. The pressure of the spring clip holds the frame into place and allows easy adjustment by hand. No more hassle with looking for the right size wedge.

Soudaseal SWI

Elastic, one-component adhesive and sealant based on hybrid polymer with a very high initial tack. Soudaseal SWI was specially developed for bonding and air- and watertight sealing of the SoudaFrame SWI pre-wall window installation system to the wall.

SoudaFrame SWI Support

Support bracket for increased load transfer for large and heavy windows as well as for sliding doors. Suitable for projects with window fall protection.

GFRP

GFRP as a composite material, mainly consists of two components: glass fibres as a mechanical reinforcement (absorption of tensile forces) and a reaction resin as a matrix for embedding the fibres (compressive forces). With the GFRP frame elements of the SoudaFrame SWI system Soudal has made optimum use of the many advantages of GFRP and thus creating the right material for the application.

Because the pre-frame can be pre-assembled, the total assembly time is considerably shorter, which reduces the non-productive period when constructing new buildings or refurbishing existing buildings.

The strength of the composites is comparable of those of steel or aluminium. The glass fibres can be custom-tailored to add strength in critical areas.

GFRP is a good thermal insulator for both cold and heat, comparable with wood and other plastics. The heat transmission is kept very low.

Other than wood and thermoplastics, composites have an excellent form stability. They do not warp, expand or shrink, even with large temperature differences.

After curing, the material is impervious to the effects of different weather conditions and UV radiation. Glass fibre-reinforced plastic profiles retain their shape, colour and function.

Production of glass fibre reinforced plastic requires 75% less energy than steel or aluminium. In addition, GFRP is 100% recyclable and can be used again as an additive in the production of cement.

In construction, composites are mainly used in applications where the combination of its superior material properties is required: where high load- bearing capacities are required, where high thermal insulation requirements are set, which must also be corrosion and weather resistant and which offer high strength and form stability (no shrinkage or expansion) in combination with low weight. That is what GFRP can be.

BACK TO TOP